Years ago, a show was aired on TV that had a precocious kid who went on far-flung adventures with his magic pencil. This pencil was the stuff of fantasies, for he only had to draw an object on paper with this pencil, and it would appear to life before his eyes. In a heart-stopping episode, he narrowly escaped the jaws of death by drawing a car that whisked him away to safety. A technology akin to this mythical thingamajig has revolutionized manufacturing, unassumingly named 3D printing, bringing to form a three-dimensional structure to an intangible imagination.

Science fiction has been a ceaseless playground for those who dare to dream. Several intuitive authors wrote of a progressive future with jaw-dropping technology, which propelled sharp engineering minds to bring these stories to life. Whether it is the clamshell walkie-talkie from ‘Star Trek’ that inspired Motorola’s flip phone or the Hoverboard as seen in ‘Back to the Future’, this is a saga that repeats itself.

Murray Leinster was the first to describe a procedure uncannily similar to the 3D printing technique in his 1945 short story Things Pass By. He describes an “efficient and flexible constructor” into which he feeds “magnetronic plastics” – “It conjures drawings in the air following drawings it scans with photo-cells. The object emerges from the end, hardening as it comes out.” Given that the first 3D printer would not make an appearance until 1971, the unnerving accuracy of his imagination is more like a soothsayer’s prophecy.

A student can learn the cross-section of a heart courtesy a lifelike dummy, instead of being ill-prepared for the moment when they encounter a real, beating one

Bring The Image To Life

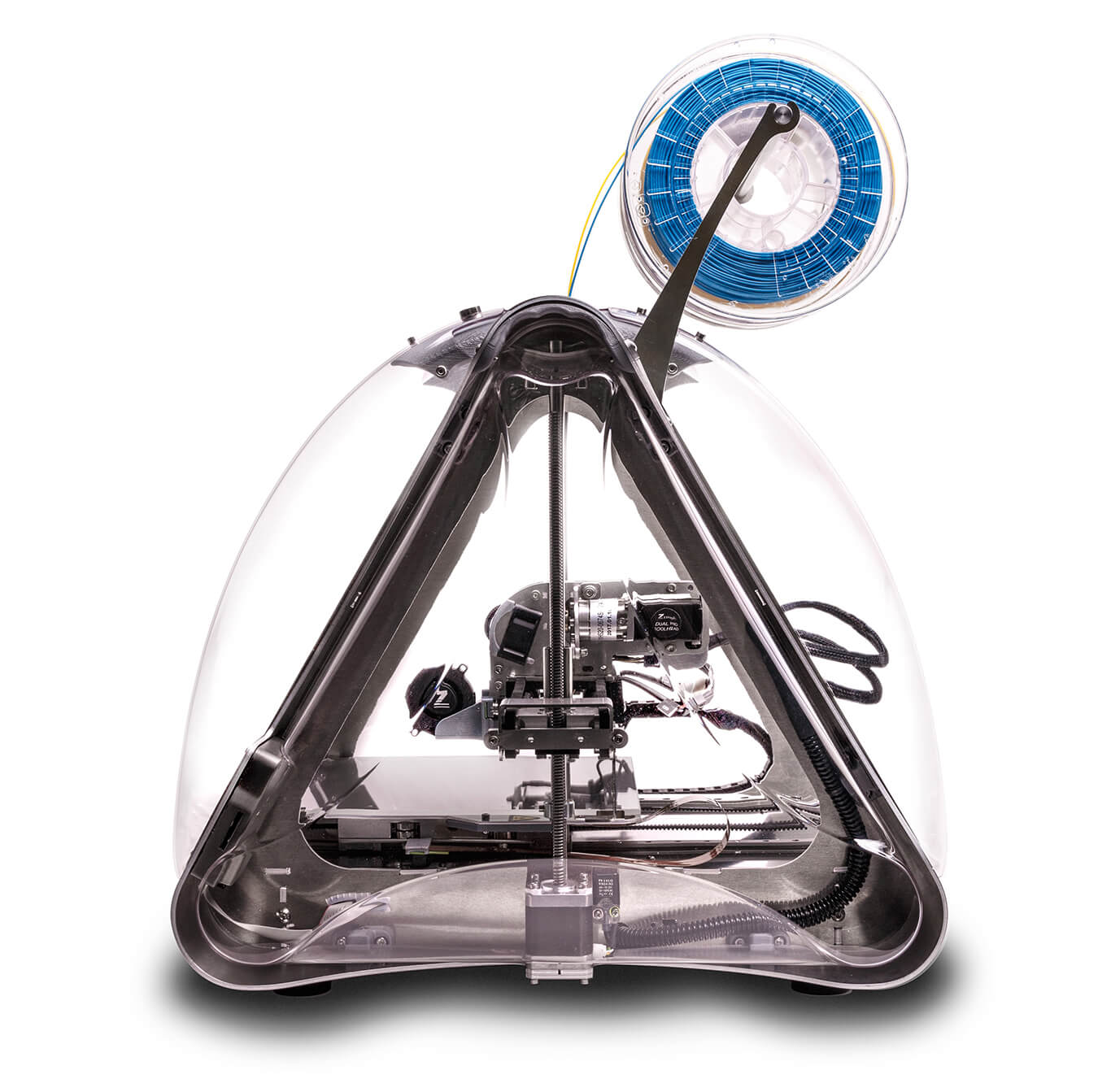

A novice might visualize objects popping out of a regular printer, and you couldn’t fault them for it. The ascent of technology is bewildering, but you can begin to understand 3D printing by building on your familiarity with 2D printing. In fact, imagining a regular printer is the best way to go about it, for 3D printing does not meander far from the trail.

The digital file of your design is uploaded in the form of 3D computer graphics, CAD files or a variation of them. 3D printing ink, called filaments, is more accurately characterized as materials such as thermoplastics, glass, metal or even wood. While 3D printing, the machine needs several print cycles, or layers, to produce a physical object. This aspect affords it the name ‘additive manufacturing’ (or AM).

In 2019, the global additive manufacturing market grew to over $10.4 billion, crossing the pivotal double-digit billion threshold for the first time in its nearly 40-year history

A Trick For Every Trouble

3D printing has proved itself to be a game changer, and as it stands, sees a lot of use from a multitude of industries – from critical manufacturing, emancipating healthcare to indulgent hobbies.

By 2010, it was clear that metal would not be the dominant material for additive manufacturing, and as the materials diversified, so did the purpose of printing. Much like the moniker ‘additive manufacturing’, the technique has strengthened layer by layer, its relentless improvement allowing for diverse utilization. It first proved its mettle in the aviation industry, manifesting as a solution to the increasing demand for fuel efficient jet engines. The timing could not be more advantageous. Where older technology could not craft new, complex shapes of lighter engines needed to increase fuel efficiency, AM could.

There is a plethora of industrial applications to 3D printing. Aerospace was an early adopter of 3D printing for engines, aircraft interiors and the like, with industries such as defence and automotive following in close succession. Defence applications include complex parts and surveillance drones, aiding armies in protecting their nation’s interests. Furthermore, electronic 3D printing has piqued the interest of defence agencies, which makes it possible to print miniature circuit boards and antennae with a precise blueprint, equipped in guided missiles. For manufacturers, this means being able to accelerate the product development process and saving valuable time by eliminating the need to outsource high-value projects to third parties.

The orthopaedics 3D printing market was valued at $691 million in 2018 and is predicted by SmarTech Analysis to grow into a $3.7 billion market by 2027

Chip Off The Old Block

3D printing fixes some of the follies of archetypal manufacturing. At the barebones, foundational differences separate 3D printing from conventional manufacturing. Traditional manufacturing is characterized by longer production runs, apt for anticipated product design, with minimal experimentation and heavy output volume. It is not designed for surprise changes or experiments. Conversely, 3D printing gives the producer a tremendous advantage for small, one off production runs and at the same time the ease of manufacturing complex pieces too.

For instance, imagine a meticulously crafted part with moderate variations by size and design, and unequal volume of each unique piece. In traditional manufacturing this kind of atypical customization would take weeks, but 3D printing allows a small adjustment to the input design to churn out the faintly varying pieces.

Revenues for 3D-printed dentistry will grow to $3.7 billion by 2021, and the technology will become the leading production method for dental restorations and devices worldwide by 2027. Source: SmarTech Analysis

It also allows taking more risks, grants room for artful customization, reduces lead time and time to market, and cuts down waste. Experiments on the factory floor can often cost time, material and manpower, but 3D printing presents itself as a viable amalgamation of critical steps. Even if a design fails, the amount of investment in its development is lesser than traditional manufacturing, so it is little grief to the manufacturer. On the flipside, a successful experiment can enhance efficiency of a machine and add years to its longevity. This flexibility is what makes the technique so sought after, and advances in this field something that industry experts are closely looking at.

Ushering In A New Dawn

Initially, 3D printer models and materials were expensive, running into hundreds of thousands of dollars for a single hulking machine. As high initial costs dwindled, the gatekeeping for merely scientific and industrial use shattered. Today, a decent entry level printer is priced around 1000 dollars, a far cry from the monumental cost of the old days. And despite these being pegged for personal use, it is established that limitations in printing capabilities begin to diminish the higher you climb, both in price and complexity.

Small and medium-sized enterprises (SMEs) are the power users of online 3D printing services, representing more than 75 per cent of the global customer base.

Additionally, professional 3D printers too have become affordable enough to have carved a path into classrooms and libraries, supporting the education system in channeling limitless possibilities for students. They have revolutionized STEM education and increased reach by offering the ability for low-cost rapid prototyping and fabricating low-cost high-quality scientific equipment from open hardware designs. A student can study the replica of a fossil or a bone, instead of the fear of damaging the real thing, which would pose a barrier in learning. Or a student can learn the cross-section of a heart courtesy a lifelike dummy, instead of being ill-prepared for the moment when they encounter a real, beating one.

There are now companies that offer cloud-based additive manufacturing services where consumers can build parts and objects remotely without the expense of purchasing a 3D printer. This means you don’t need your own 3D printer to create a toy or a part, which makes perfect sense since not all of us own such printers. The journey we are on endeavours to make 3D printers as easily accessible in establishments and offices as 2D printers currently are.

The Imprint of Life?

3D printing has spawned a host of adjoining techniques, each more astonishing than the one before. Consider bioprinting, where biomaterials such as cells and growth factors are combined to create tissue-like structures imitating their natural counterparts. Or compatible prosthetics designed for a patient that can be manufactured repeatedly for multiple growth spurts akin to a real limb. Chronic conditions such as epilepsy can be managed with immensely porous pills that dissolve and are digested quickly, manufactured by Binder Setting, another 3D printing offering. There have been successful cases of a patient receiving a titanium pelvis implant, another getting a new titanium lower jaw. A motorcyclist patient whose face had been seriously injured in a road accident had it rebuilt with 3D printed parts.

79 per cent of surveyed companies expect their use of 3D printing for production parts or goods to at least double in the next 3 to 5 years.

The revolution in construction beckons our attention. 3D printing in construction provides several advantages like allowing more complexity and accuracy, faster construction, lower labor costs, greater functional integration, and less waste. 3D printing reached a notable landmark when the first fully completed residential building was constructed in Yaroslavl, Russia in 2017. 600 elements of the walls were printed in a shop and assembled on site, followed by completion of the roof structure and interior decoration.

Fil-(AMENT) of The Future

The future of 3D printing is full of possibilities. The medical marvels mean that more people with accidents or birth defects can lead dignified, fulfilling lives, while the technological innovation heralds an upheaval of the manufacturing process similar to that seen with the introduction of the assembly line. Hopes are pinned on 3D printing to provide a cost-effective solution to the housing crisis, sheltering homeless millions around the world.

The US has the largest installed base of 3D printers of 422,000 units in the world. The USA, UK, Germany, France and China are the top 5 countries with the highest 3D printing adoption and investment rates.

Any technology can go either divine or demonic, but prudence and empathy of intention can ensure that 3D printing is used as a tool for sustainability and is crowned a success for the benefit of the human race. In a way, we are all that adventurous kid now, bringing our fantasy to life with a scribbled sketch on a piece of paper, and a little bit of magic.